Custom Machines

- •

- Custom Machines

- •

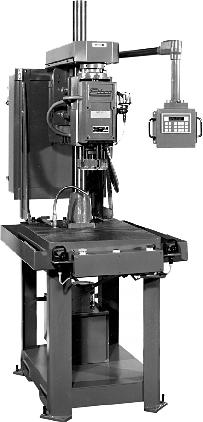

- ATU-4 Production Tapping Machine and Tapping Unit

ATU-4 Production Tapping Machine and Tapping Unit

Precision lead screw tapping to keep your operation on the cutting edge of tapping hole production.

The ATU series tapping units and machines from ETTCO provide for precise efficient hole production at a fraction of the cost of CNC.

Equipped with a swivel-mounted programmable operator interface and controller, the reliable ATU-4 system promotes quick and precise setups. The operator interface displays alarms, and messages, and allows for bidirectional spindle jogging.

The ATU-4 is available as a standard vertically mounted machine or can be mounted explicitly in any position from vertical to horizontal The standard machine includes a welded steel base and table with 1-slot, coolant pump, and plumbing and safety interlocked double palm start buttons.

At a glance …

- 4″ of lead screw travel

- 30 cycles per minute possible

- Swivel-mounted operator interface terminal, with English or Spanish display

- Programmable controller

- 3.5 HP, 1140 RPM high reversing motor 230/460 VAC, 3-Phase, 60Hz power

Features & Specifications:

Unit & Machine:

- 4″ of lead screw travel

- 30 cycles per minute possible

- Solid-state programmable

- 35, 1140 RPM high reversing motor 230/46/360 reversing motor

- Pulley drive (370-1500 RPM)

- No hole protection

- Electrical control panel and controls for double palm push button operation

- Lead screw drip oiler, with an adjustable flow rate

- Resettable cycle counter, accessible through interface terminal

- Optional speed reducer to permit speeds as low as 55 RPM

Machine:

- Swivel-mounted operator interface terminal, with English or Spanish display

- 4″ Diameter column with raising & lowering mechanism

- 24″W X 36″H Machine base of welded steel construction

- 10 Gallon capacity coolant system

- Excellent power source for ETTCO multiple spindle heads

Price: Contact Factory